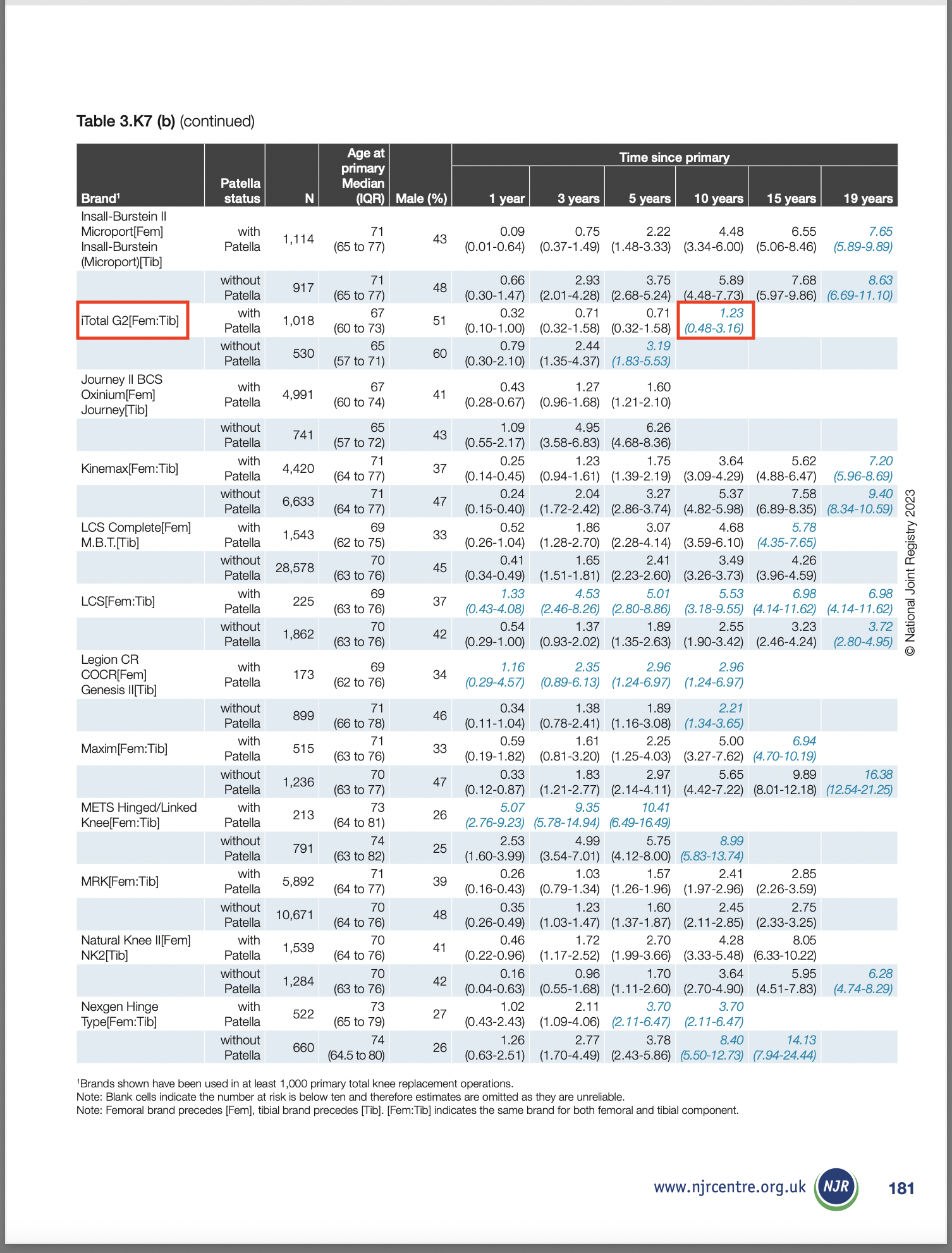

The 2023 NJR 20th Annual Report shows that the 10-year revision rate for the Conformis iTotal custom-made knee is just 1.23% compared to an average revision rate of approximately 5% for all prostheses on the register, which equates to an approximately 75% reduction in the risk of the patient needing a revision (re-do surgery) after 10 years!

These results are highly significant (not that you’ll hear this from any of the many other orthopaedic implant companies out there, or from the surgeons using their implants!)

Bespoke knees get best results

It is well-known that the results of knee replacement surgery are not guaranteed, and indeed with a standard off-the-shelf knee prosthesis only about 80 to 85% of patients are happy with their outcome. This doesn’t necessarily mean that the patient has suffered a complication, such as an infection or a blood clot: it simply means that the operation hasn’t ended up meeting the patient’s expectations, and that the patient is unhappy with their outcome for any reason, be that stiffness, discomfort or reduced function. If one considers that up to 100,000 knee replacement operations may be performed per year in the UK, that equates to 15,000 to 20,000 unhappy patients a year, which is clearly a massive issue.

Biggest leap forward

Biggest leap forward

The biggest leap forward in knee replacement technology in the last 30 years is the development of custom-made patient-specific knee replacements, and Conformis, a Boston-based U.S. implant company, has led the way in this ground-breaking technology.

Standard knee replacement

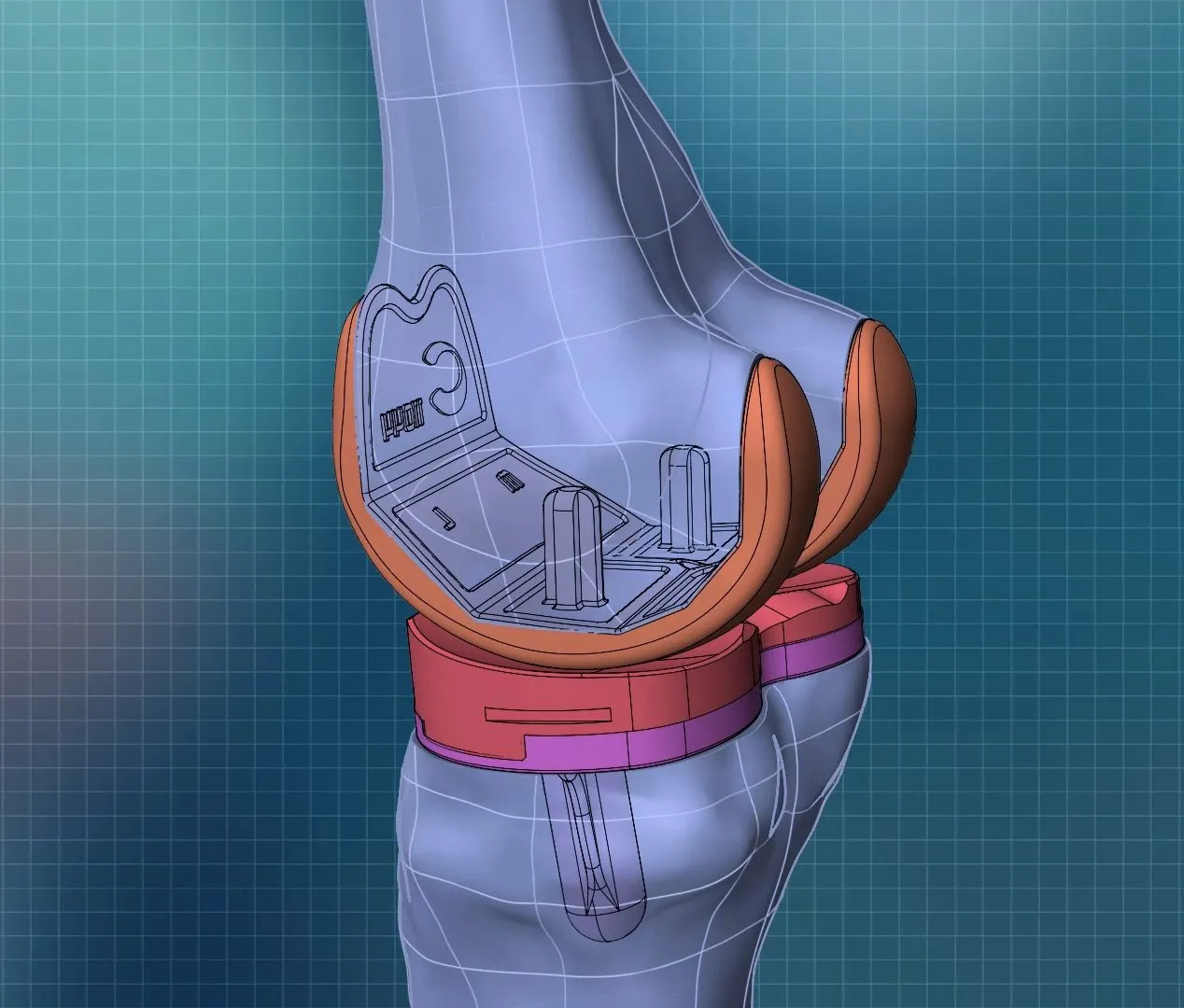

With a standard knee replacement, the prosthesis is made in size A, size B, size C etc… if your knee just happens to be in the middle of ‘size A range’, then you’ll be lucky: you’ll get a prosthesis that’s the right size. But if you’re halfway between size A and size B, then you’ll end up receiving a prosthesis that’s either too small or too big.

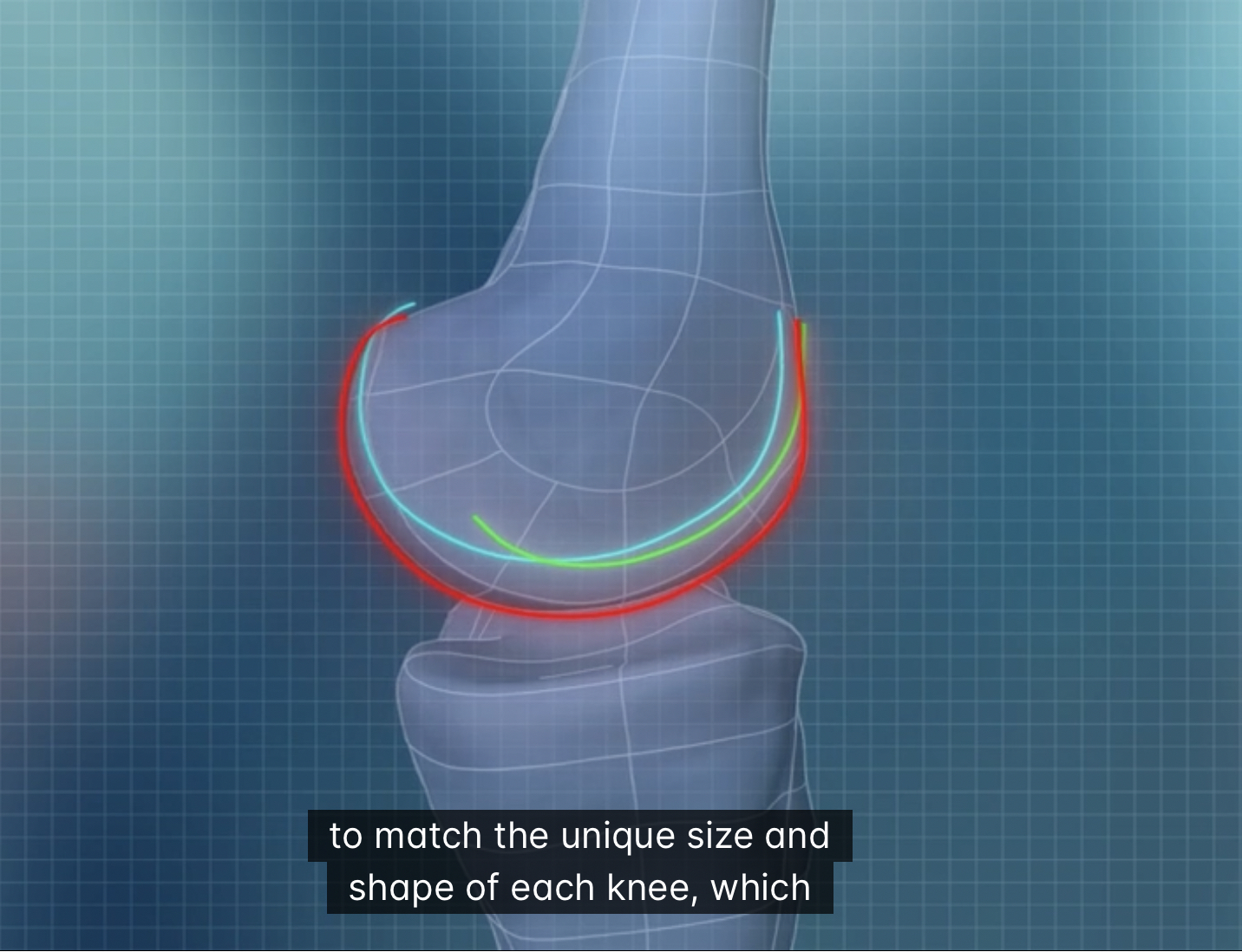

Similarly, with a standard knee replacement, the prosthesis only comes in one single shape, based on what the design team think is closest to ‘the average shape’. The reality, however, is that not only do people’s knees come in different sizes, but they also come in a wide range of different shapes, with significantly varying contours and geometries. So, with a standard implant, it’s pure luck as to how closely the implant may (or may not) match the shape of your knee, and if there’s a significant shape mismatch, then that knee is less likely to move the way your personal knee moves (knee kinematics) and it’s less likely to feel ‘normal to you’.

Similarly, with a standard knee replacement, the prosthesis only comes in one single shape, based on what the design team think is closest to ‘the average shape’. The reality, however, is that not only do people’s knees come in different sizes, but they also come in a wide range of different shapes, with significantly varying contours and geometries. So, with a standard implant, it’s pure luck as to how closely the implant may (or may not) match the shape of your knee, and if there’s a significant shape mismatch, then that knee is less likely to move the way your personal knee moves (knee kinematics) and it’s less likely to feel ‘normal to you’.

Custom-made patient-specific iTotal knee

By comparison, the custom-made patient-specific iTotal knee from Conformis is designed to match the exact size, shape and contours of each individual patient’s knee perfected, every time, using highly precise CT data of the patient’s own knee (combined with views of the hip and the ankle, to ensure accurate alignment and rotation as well).

Katthagen Study

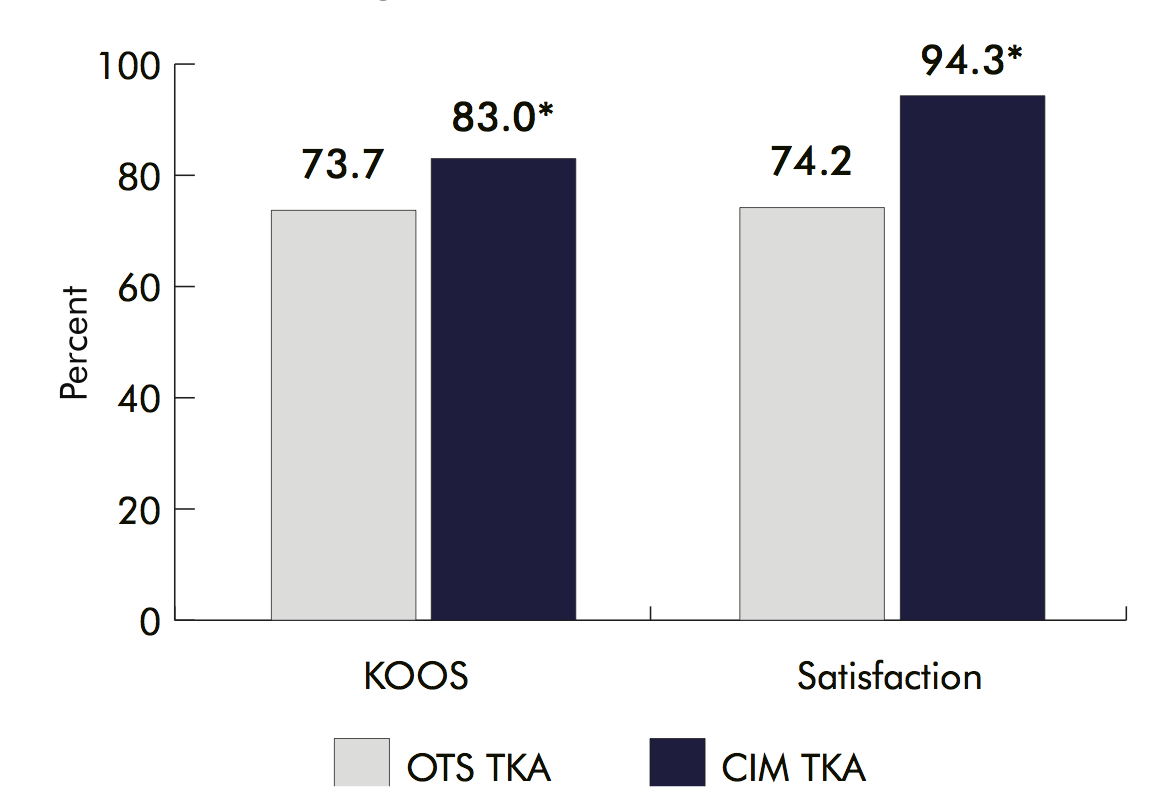

A study presented by Katthagen at The World Arthroplasty Congress in 2015 showed a satisfaction rate of just 74.2% for those patients receiving a standard off-the-shelf prosthesis. However, those patients having a Conformis custom-made knee had a satisfaction rate of 94.3%.

This equates to a reduction from 25.8% of dissatisfied patients down to just 5.7%, which represents a reduction of 78% in the risk of a patient ending up unhappy with the results of their knee replacement surgery!

This equates to a reduction from 25.8% of dissatisfied patients down to just 5.7%, which represents a reduction of 78% in the risk of a patient ending up unhappy with the results of their knee replacement surgery!

long-term results can only be obtained from medical equipment that has been around for a long time

Probably the main concern that we, as surgeons, had with the introduction of the Conformis custom-made knee was the fact that as with all new tech, there will, inevitably, be a lack of long-term data available. It’s important to appreciate that long-term results can only be obtained from medical equipment that has been around for a long time, meaning that it will, inevitably, be old tech.

What are the long term results?

One potential question was whether improved patient outcomes might lead to increased patient activity levels, with, therefore, a faster rate of general ‘wear and tear’ on the knee prosthesis… would this mean that these better knees might wear out faster, and might we potentially end up seeing these knees wearing out and failing sooner, with a higher long-term revision rate?...

One potential question was whether improved patient outcomes might lead to increased patient activity levels, with, therefore, a faster rate of general ‘wear and tear’ on the knee prosthesis… would this mean that these better knees might wear out faster, and might we potentially end up seeing these knees wearing out and failing sooner, with a higher long-term revision rate?...

The official results are in

Well… now, finally, the proof is in the pudding and the results are in and the evidence is clear, not only do Conformis custom-made knees give the best results in terms of patient satisfaction, but they have also now been shown to have the lowest 10-year revision rate of any prosthesis ever recorded on the National Joint Register!