The results are in..

The biggest leap forward in knee replacement technology in the last 30 years arguably is the ability to precisely match individual patient anatomy with custom-made knee replacements. London Sports Orthopaedic's Consultant Knee Surgeon, Mr Ian McDermott explains how this technology is now officially acknowledged as producing the best outcomes.

Problems normally associated with traditional approaches

With a standard knee replacement, the replacement prosthesis is available in fixed sizes, so if your knee just happens to be in the middle of ‘size A range’, then you’ll be lucky: you’ll get a prosthesis that’s the right size. Mr Mc Dermott says, "But if you’re halfway between size A and size B, then you’ll end up receiving a prosthesis that’s either too small or too big."

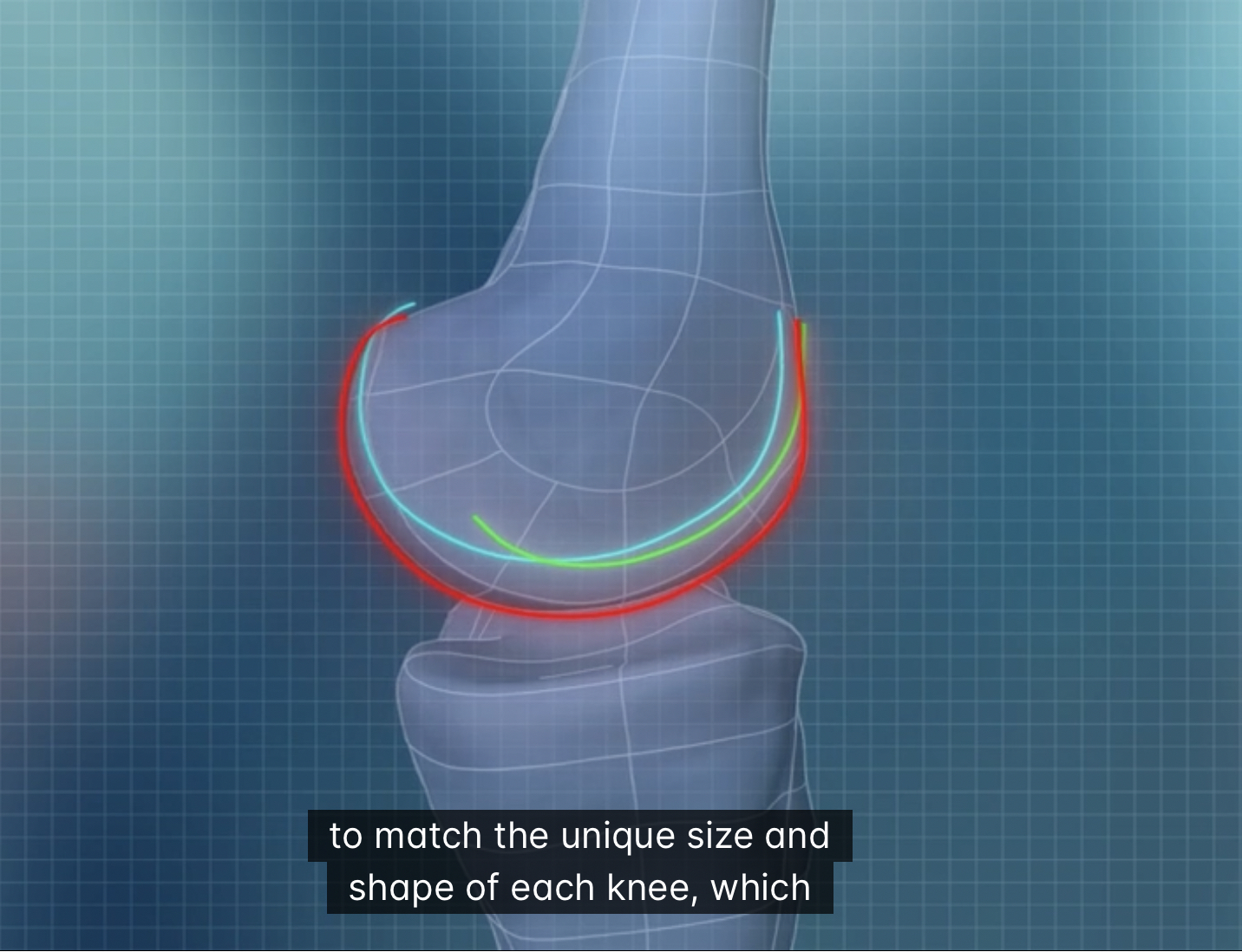

Similarly, with a standard knee replacement, the prosthesis only comes in one single shape, based on what the design team think is closest to ‘the average shape’. The reality, however, is that not only do people’s knees come in different sizes, but they also come in a wide range of different shapes, with significantly varying contours and geometries. So, with a standard implant, it’s pure luck as to how closely the implant may (or may not) match the shape of your knee, and if there’s a significant shape mismatch, then that knee is less likely to move the way your personal knee moves (knee kinematics) and it’s less likely to feel ‘normal to you’.

Similarly, with a standard knee replacement, the prosthesis only comes in one single shape, based on what the design team think is closest to ‘the average shape’. The reality, however, is that not only do people’s knees come in different sizes, but they also come in a wide range of different shapes, with significantly varying contours and geometries. So, with a standard implant, it’s pure luck as to how closely the implant may (or may not) match the shape of your knee, and if there’s a significant shape mismatch, then that knee is less likely to move the way your personal knee moves (knee kinematics) and it’s less likely to feel ‘normal to you’.

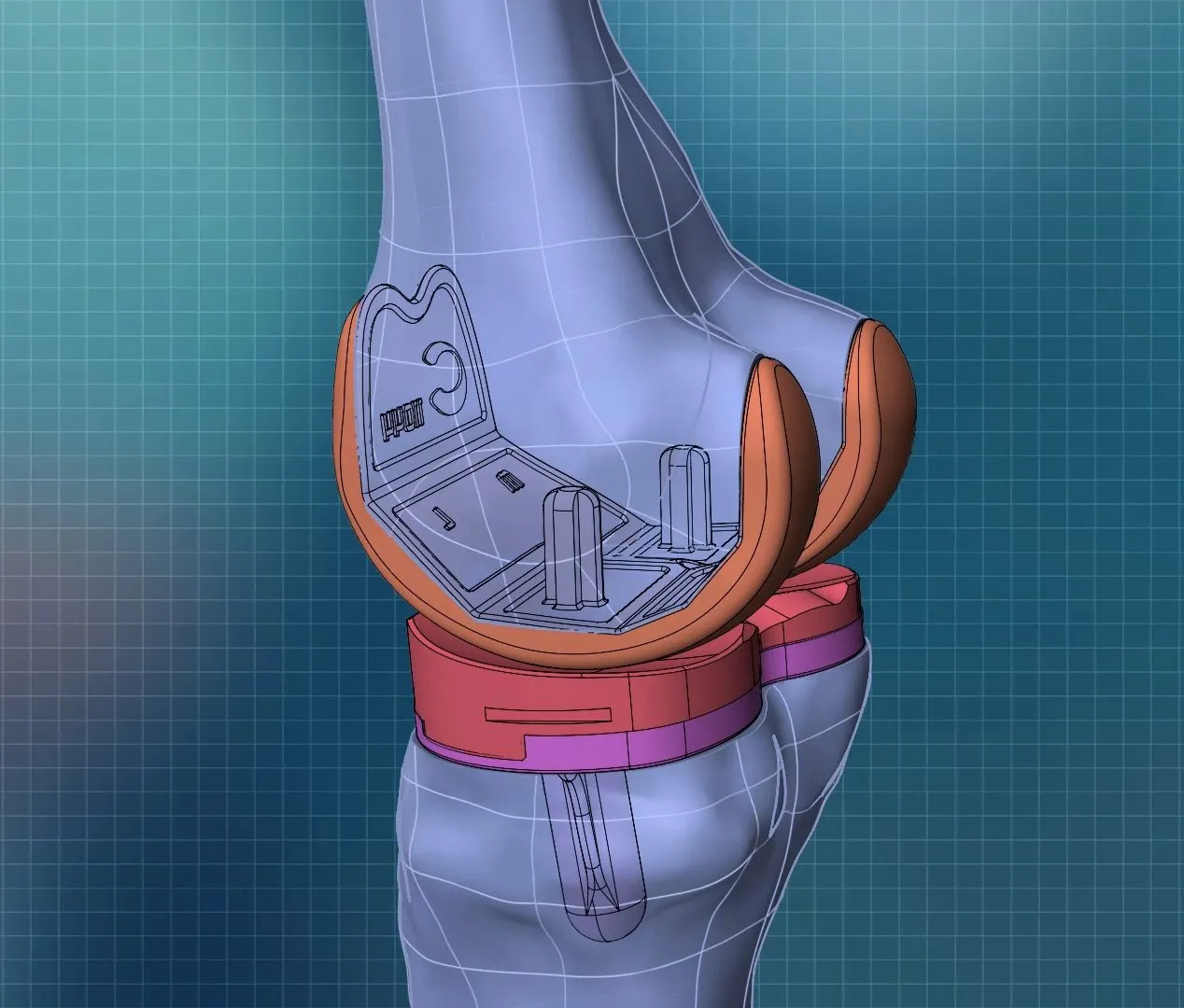

Custom-made patient-specific iTotal knee

By comparison, the custom-made patient-specific iTotal knee from Conformis is designed to match the exact size, shape and contours of each individual patient’s knee perfected, every time, using highly precise CT data of the patient’s own knee (combined with views of the hip and the ankle, to ensure accurate alignment and rotation as well).